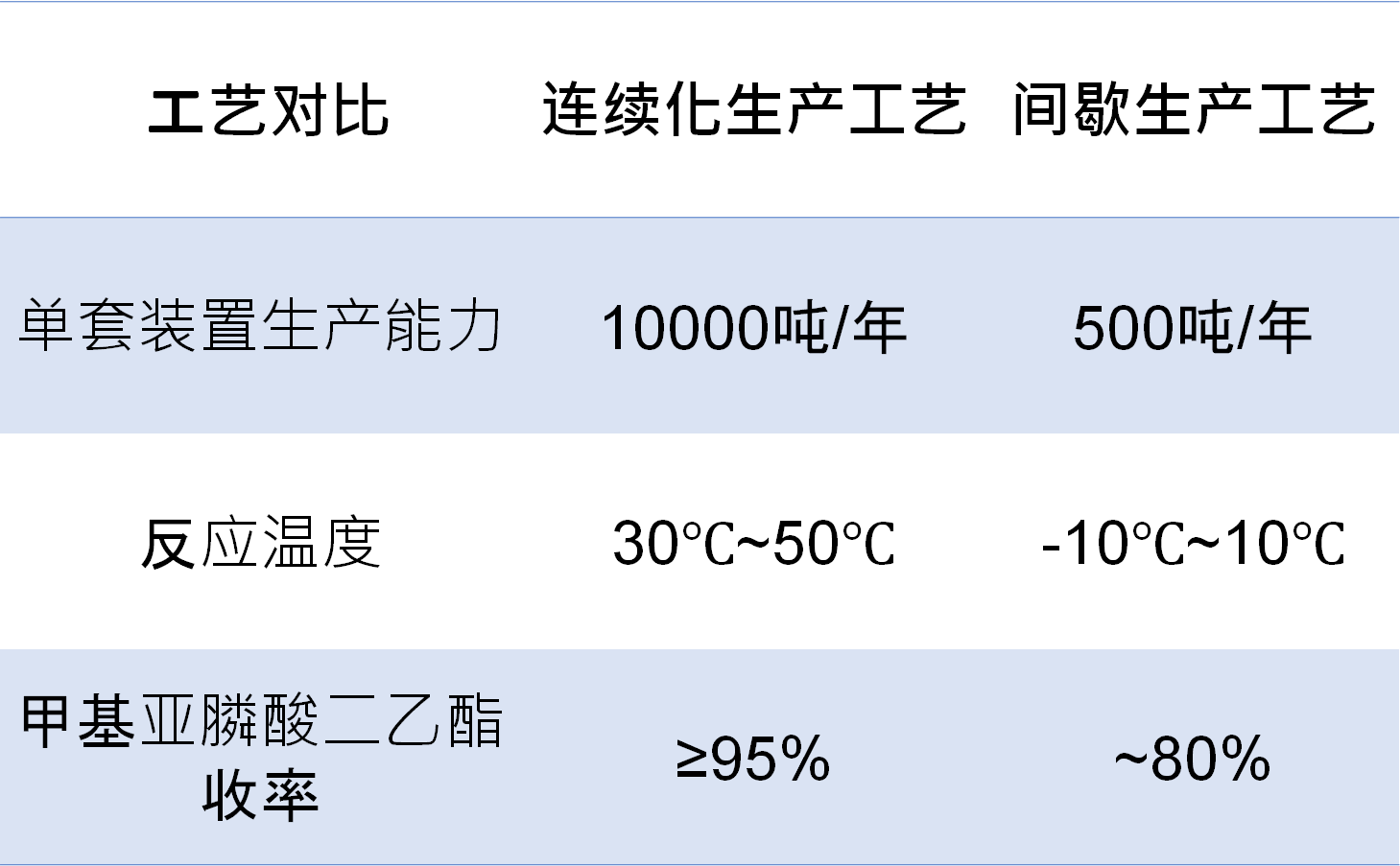

草铵膦具有毒性低、活性高、杀草谱广泛的优点,被视为是目前毒性较高除草剂的理想替代品,而甲基亚膦酸二乙酯是生产草铵膦的重要中间体。本技术使用连续流工艺,通过实现液相物料的快速混合,及时脱除体系副产物氯化氢,避免了目标产物甲基亚膦酸二乙酯的酸解。与传统间歇滴加工艺相比,目标产物收率和装置生产能力均有大幅度提高。

Glufosinate-ammonium, with the advantages of low toxicity and high activity, is considered to be an ideal substitute for current herbicides, and diethyl methylphosphite(DEMP) is an important intermediate. Through the continuous flow technique, rapid mixing of liquid materials is achieved. And hydrogen chloride is removed by ammonia, which avoids the acidolysis of DEMP. The DEMP yield and the production capacity of the device are both greatly improved.

技术方案及特色

Ø反应过程强化

ü连续流实现反应物甲基二氯化膦高效转化

ü预溶氨工艺打破气液传质限制

ü强化液体混合快速高效脱除副产氯化氢,减少酸解副反应

Ø精馏分离过程

ü采用循环工艺降低精馏能耗

ü减压精馏降低釜温减少产物分解

Ø 计算流体力学指导反应器结构理性设计